Effective Tahoe Instrument Cluster Repair Providers: Dealing With Gauge Precision

Effective Tahoe Instrument Cluster Repair Providers: Dealing With Gauge Precision

Blog Article

Ultimate Source for Advanced Vehicle Tool Cluster Repair Work Methods

In the world of modern automobile upkeep, the ins and outs of instrument collection fixing stand as a crucial facet of making sure the optimum performance of an automobile (tahoe instrument cluster repair). As modern technology breakthroughs, so do the complexities of these crucial components, requiring a thorough understanding of innovative repair work strategies. With a myriad of possible problems that can develop within instrument collections, having a reputable resource that supplies extensive advice on troubleshooting and rectifying these difficulties comes to be critical. By exploring the devices needed, common troubles came across, and step-by-step repair work methodologies, one can outfit themselves with the understanding required to navigate the complex globe of auto tool collection repair with self-confidence and accuracy.

Significance of Advanced Tool Cluster Repair

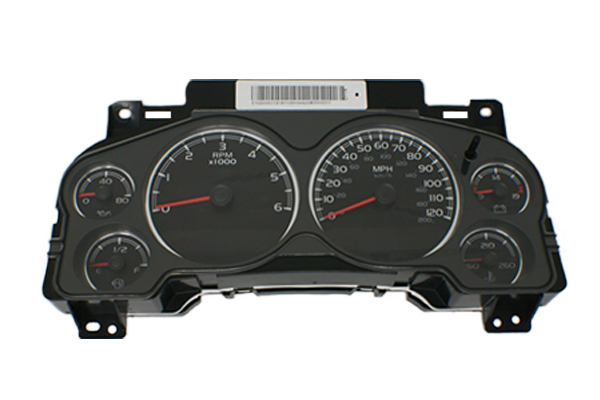

Comprehending the value of innovative instrument cluster fixing is essential for preserving the performance and accuracy of modern-day lorry systems. The instrument collection serves as the hub of information for chauffeurs, presenting essential information such as rate, gas degrees, engine temperature, and advising indicators. With the development of innovation, instrument collections have evolved to integrate complicated electronic parts and digital displays, making repairs a lot more complex and specialized.

Proper repair and maintenance of the instrument cluster are crucial for guaranteeing the safety and security and efficiency of the lorry. Problems with the tool cluster can lead to unreliable readings, breakdowns in crucial systems, and safety threats on the road. Advanced tool cluster repair service techniques entail diagnosing digital faults, recalibrating sensors, and reprogramming software application to recover ideal performance.

Devices and Equipment Needed

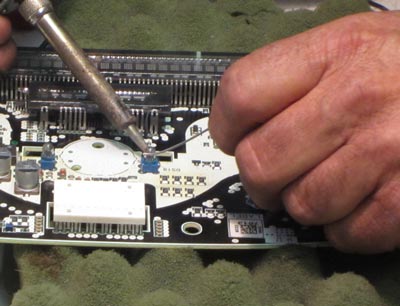

To effectively resolve the complex repair service demands of modern-day lorry instrument collections, a specialized collection of devices and devices is necessary. Several of the secret tools needed for innovative automobile instrument cluster repair work include accuracy screwdrivers, trim elimination tools, soldering tools, electronic multimeters, and diagnostic scanners. Precision screwdrivers are essential for disassembling the collection without causing damage. Cut removal devices assist in safely prying off bezels and panels. Soldering equipment is essential for repairing broken connections or changing components. Digital multimeters are made use of to determine voltage, continuity, and resistance throughout diagnostic procedures. Diagnostic scanners are important for identifying and troubleshooting digital problems within the instrument cluster. In addition, having a top quality soldering iron, desoldering pump, and solder cord is very important for accomplishing detailed soldering work. Appropriate illumination, a magnifying glass, and a tidy office are additionally crucial for ensuring accuracy and accuracy throughout repair services. By having these specialized devices and equipment on hand, professionals can efficiently diagnose and resolve complex problems in vehicle instrument collections.

Usual Concerns and Solutions

Several usual issues often run into in vehicle instrument collections can be efficiently solved through targeted options. One more common problem is flickering or dark lights on the tool cluster. By recognizing these usual issues and applying the ideal solutions, automobile tool cluster performance can be recovered efficiently.

Step-by-Step Repair Work Guide

A methodical strategy to fixing and identifying auto tool cluster problems is vital for accomplishing accurate and efficient outcomes. To begin the repair work process, the first step is to very carefully inspect the tool collection for any type of visible damage such as burnt-out light bulbs, broken screens, or loose links. Next, it is crucial to perform an analysis check utilizing specific tools to recognize any underlying digital issues. As soon as the issue areas are pinpointed, the fixing can begin by either changing malfunctioning parts, repairing damaged wiring, or rectifying sensors.

Tips for Preventative Maintenance

After performing a thorough diagnostic scan and finishing required repairs on the auto instrument collection, applying normal preventative maintenance measures is crucial to look at this website guarantee lasting capability and ideal efficiency of the lorry's necessary evaluates and indications. To start, it is vital to consistently evaluate the instrument cluster for any kind of signs of wear, such as fading display screens or malfunctioning lights. Maintaining the collection clean from dirt and particles can likewise prevent damages to fragile elements. Additionally, checking the links and circuitry for any type of indicators of corrosion or loosened connections can aid stop electrical concerns that might affect the cluster's performance.

Furthermore, updating the software application of the tool collection when necessary can make certain compatibility with any new attributes or systems in the car. It is additionally suggested to follow the maker's navigate to this website suggested maintenance timetable and standards for the instrument collection to maintain its long life. By incorporating these preventative maintenance tips into your regular lorry treatment, you can assist extend the life expectancy and dependability of your auto instrument cluster.

Verdict

To conclude, innovative vehicle tool cluster repair service methods are necessary for maintaining the functionality of modern-day automobiles. By using the proper tools and tools, dealing with typical issues, and following a detailed repair service overview, technicians can properly identify and deal with tool collection troubles. Carrying out preventative upkeep strategies can help lengthen the life-span of the tool cluster and protect against future problems from arising.

By exploring the tools needed, common troubles encountered, and detailed repair methods, one can outfit themselves with the expertise needed to browse the complex globe of car instrument collection repair with confidence and precision.

A methodical technique to identifying and fixing auto instrument collection problems is necessary for attaining precise and reliable results. By following this step-by-step guide meticulously, automobile specialists can effectively repair and detect instrument collection problems with accuracy and self-confidence.

In verdict, innovative auto instrument collection fixing strategies are important for preserving the functionality of modern automobiles. By utilizing the proper devices and devices, resolving common concerns, and complying go to my blog with a detailed repair work guide, service technicians can effectively repair and detect tool cluster issues.

Report this page